Forging a Flawless Future: Streamlining Steel Production with a Symphony of Data

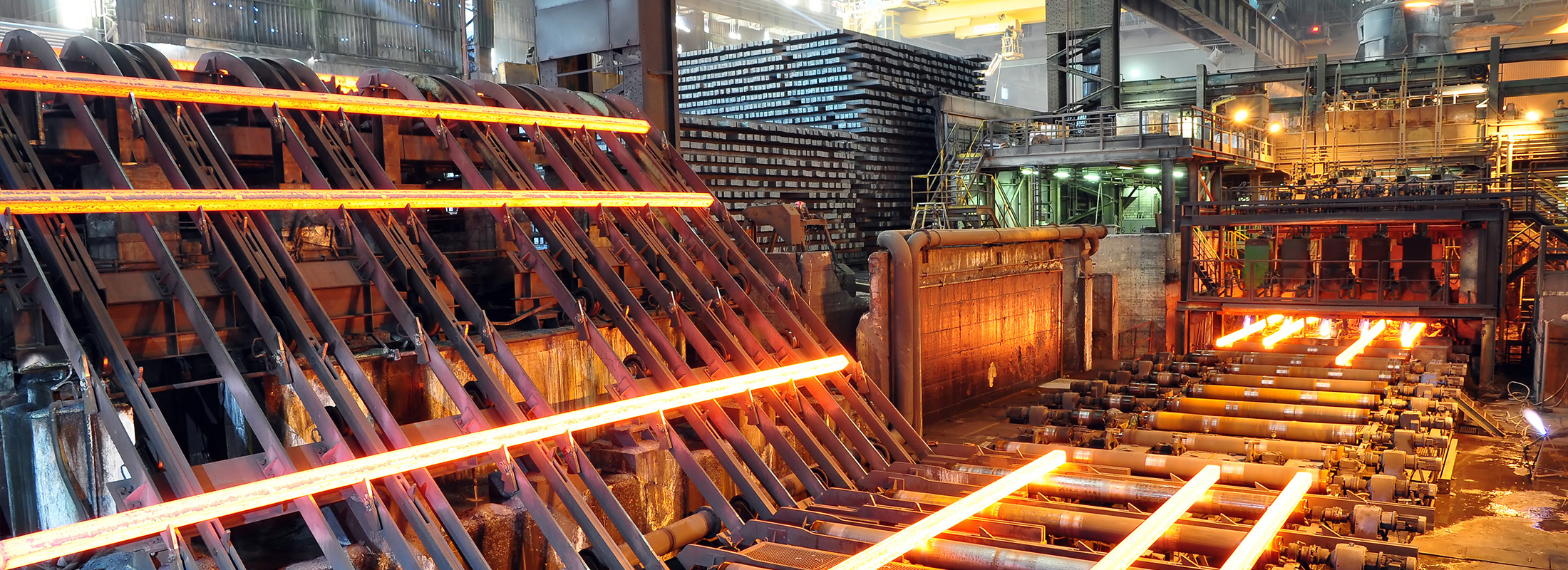

The steel industry thrives on precision, yet managing semi-automatic lines with modern equipment and disparate data systems presented a discordant challenge. Discrete modules within the existing MES offered limited financial and accounting insights, while manual procurement and warehousing activities created a paper-burdened workflow. This symphony of inefficiency demanded a refined score.

Our solution orchestrated a seamless performance. A new MES, integrated with PLCs, automated process monitoring and control. Mobile devices and an IoT application provided real-time data on the shop floor, akin to a conductor directing musicians. Furthermore, synchronized data across departments fostered collaboration, empowering cost accounting management. New modules for warehousing, procurement, and cost control completed the composition, ensuring all departments were in perfect harmony.

The results echoed with remarkable efficiency. Paperwork was reduced by 90%, freeing resources for more productive pursuits. Reporting on production achievements became a streamlined melody, offering valuable insights. Most importantly, integrated production operations and back-office departments formed a cohesive, efficient whole. This data-driven symphony not only harmonized operations but also positioned the steel company for a future of flawless efficiency.