01. What We Do

INTELLIGENT MOM SOLUTION

70 +

25 +

and development

10 +

02.Our Services

Empowering Innovation

& Fostering Futures

03. BENEFIT & VALUE

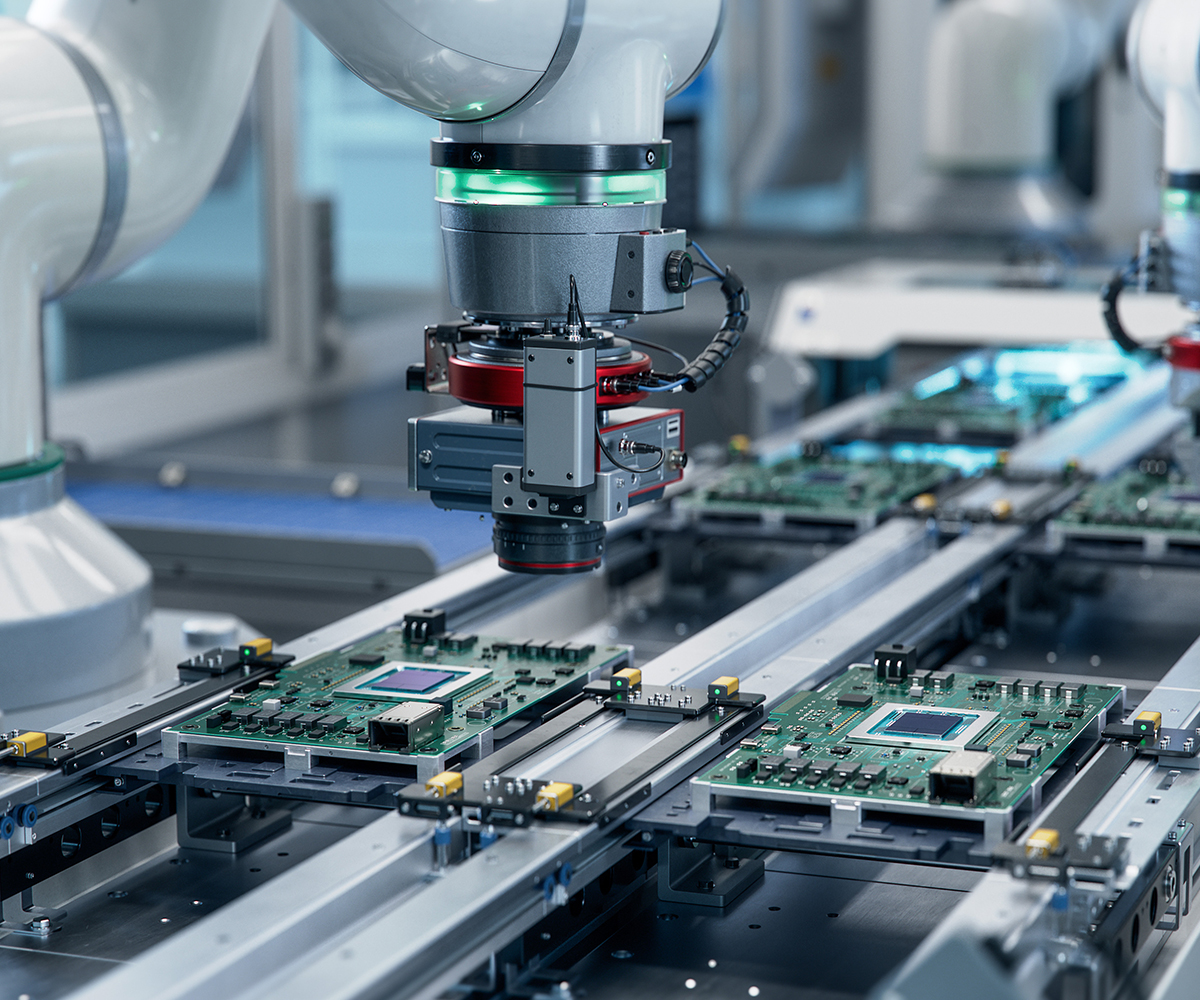

Industry-specific MES Solution

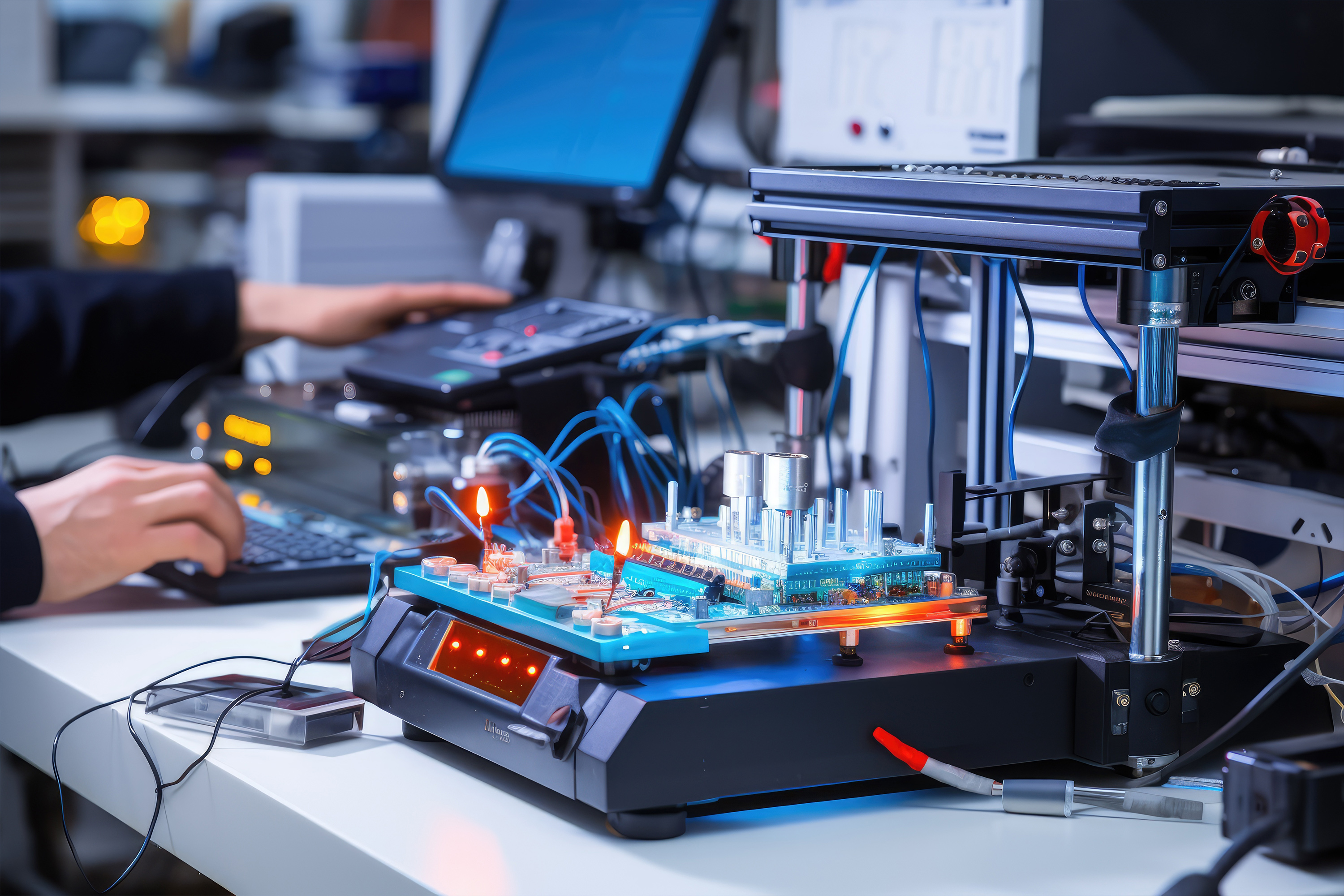

akaMES provides a comprehensive AI-powered solution for manufacturing enterprises to unlock a data-driven, connected, and collaborative workforce, improve final product quality and increase total factory capacity

More cost

effective

More

efficient

Smarter

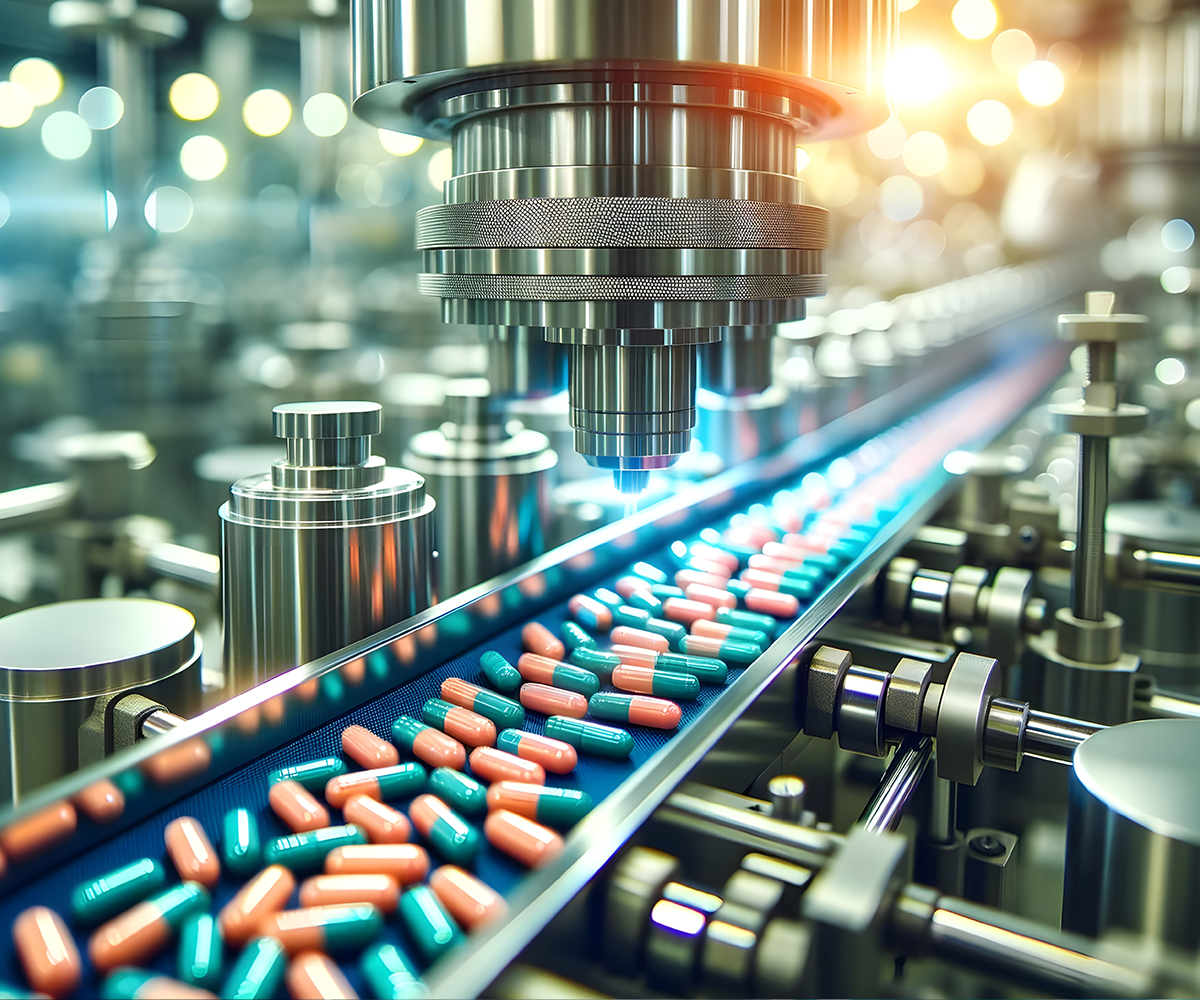

04. INDUSTRIES

Success Story

05. our partners and customers

Proud to be the trusted partner of esteemed global leaders

Microsoft

IBM

Sumitomo

Denso

We offer comprehensive MES solution to help boosting productivity in the manufacturing industry.

The akaMES solution helps all the production processes to be balanced in capacity to eliminate possible bottlenecks, delays and errors and ultimately empowers manufacturing enterprises to create a digital ecosystem where managers, operators, suppliers and customers engage flexibly across the value chain.

The Perfect Partner

Reputable & Trustworthy

Energetic & Committed

Innovative & Sustainable

akaMES helps to increase production efficiency by 15-20% and increase product quality through transparency of production data, which will be the prerequisite for continuous improvement. Moreover, akaMES is the optimal option to integrate with existing production systems.

Sumitomo Heavy Industry (Vietnam)

akaMES has outstanding features at the cost of only 1/3 of price quotes from VinFast’s foreign partners.

Vinfast Lithium Battery Ltd. CompanyPack

This is the first major innovation in 10 years since the company’s foundation. With FPT ’s expertise to make this powerful innovation, we believe the project will be successful.

Nippon Steel Spiral Pipe Vietnam

06. Everything New

Read the latest

news

The 10 Biggest Future Trends In Manufacturing